TRANSCRIBER’S NOTE

The fifteen ‘Portraits and Biographical Notes’ have been moved to the end of the main text, in front of the Footnotes and book catalog.

Footnote anchors are denoted by [number], and the footnotes have been placed at the end of the book, after the Portraits.

All changes noted in the ERRATA have been applied to the etext. Each change is indicated by a dotted gray underline.

Many minor changes to the text are noted at the end of the book. These are indicated by a dashed blue underline.

Macleod and Macdonald Engraver Glasgow

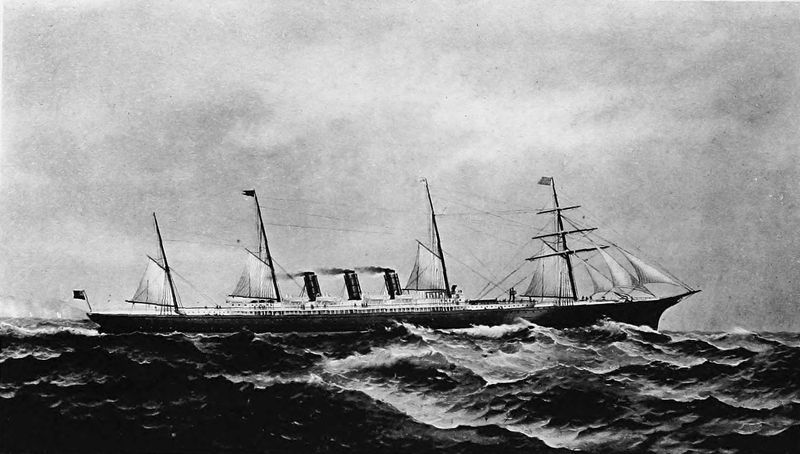

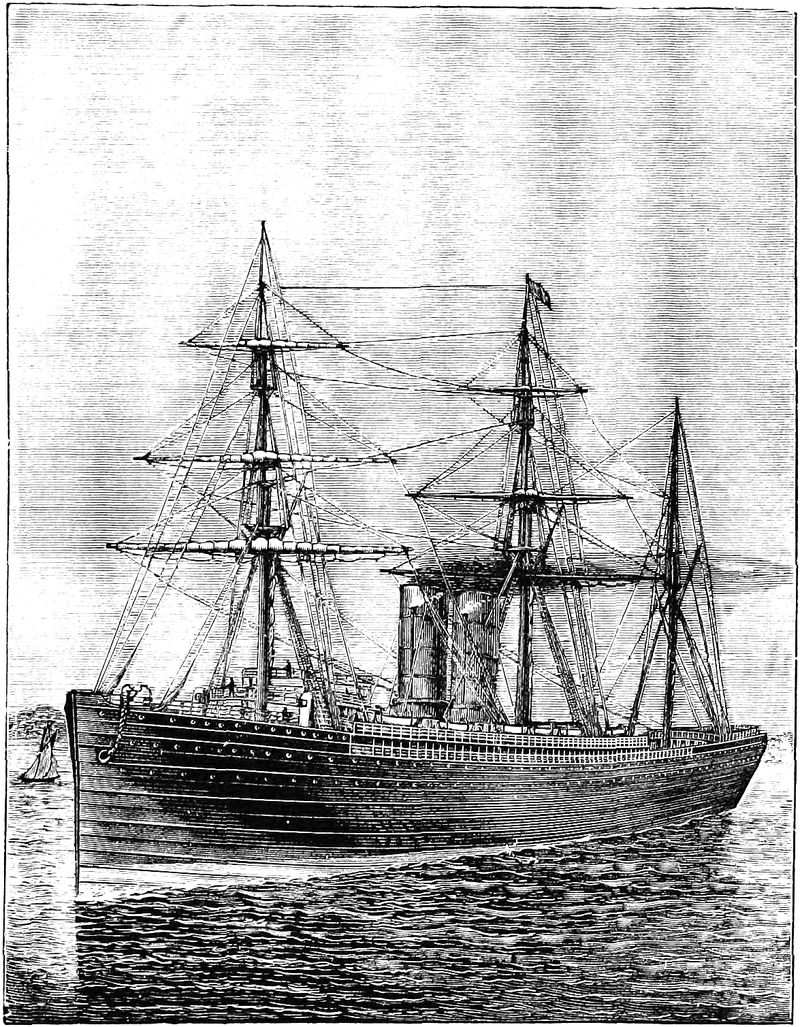

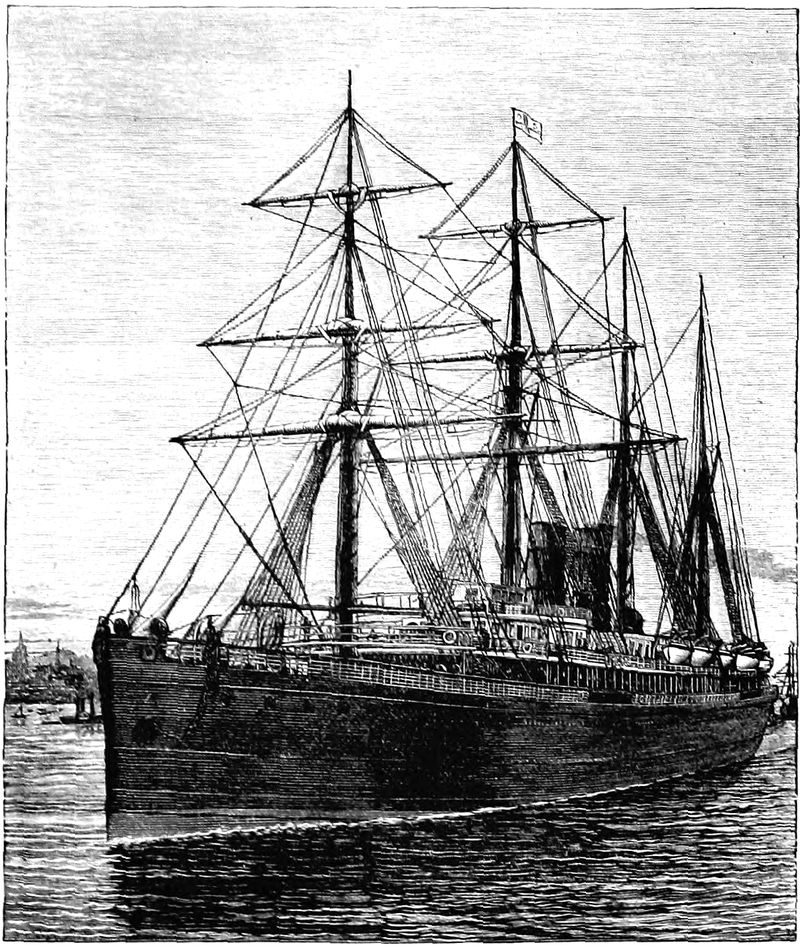

S.S. “City of Rome”—Anchor Line.A REVIEW OF RECENT PROGRESS IN STEAMSHIP DESIGN AND CON-

STRUCTION, TOGETHER WITH DESCRIPTIONS OF NOTABLE

SHIPYARDS, AND STATISTICS OF WORK DONE IN

THE PRINCIPAL BUILDING DISTRICTS.

BY

DAVID POLLOCK,

NAVAL ARCHITECT.

With Portrait and Biographical Notes of Eminent Shipowners,

Shipbuilders, Engineers, and Naval Architects;

also, Views of Notable Ships.

London: E. & F. N. SPON, 125 Strand.

New York: 35 Murray Street.

1884.

(All rights reserved.)

The great activity in shipbuilding and marine engineering during recent years, and the substantial progress, both in science and practice, which has marked the period, have often formed the subject of articles in the technical and daily press, and of papers read before professional institutions. So far as I am aware, however, no single work dealing historically with modern shipbuilding in a way at once trustworthy and popular, and in a form handy and accessible, has yet been published. The present work aims at supplying this want. In undertaking it originally, I felt encouraged by the acceptance which various articles, contributed to the columns of the Glasgow Herald, The Engineer, The Steamship, Iron, &c., had met with from many whose good opinion I had reason to value highly. With the kind permission of the proprietors of the above journals, I have made use to some extent of the articles in question—but largely amplified and corrected—in preparing the following pages.

The work is concerned exclusively with shipbuilding for the merchant marine, and no attempt is made to trace the progress connected with naval shipbuilding, although some of the many important influences which the one exerts upon the other have been indicated. Even as thus defined and restricted, the field of review is so vast that the limits which I had determined should bound the work with respect to price, and consequently with respect to size, have compelled me to treat briefly and in a general way many matters which it might have been of interest to enlarge upon. The list of authoritative papers and lectures to which readers can at first hand refer—given at the end of each chapter—may, it is hoped, compensate to some extent for these deficiencies.

The book being mainly historical, originality in the strict sense of the term cannot, of course, be urged for much of the contained matter; but efforts have been made throughout to[iv] present trustworthy statements of the very latest steps in advance. This is specially true of the chapter on scientific progress. My object, however, having been more to enlighten general readers than to seek to interest or inform professional ones, it is perhaps wanting in the scientific fulness needed to give it special value, viewed from the standpoint of the trained naval architect.

While the biographies and portraits given throughout the book may be considered fairly representative of those who as shipbuilders, shipowners, naval architects, or marine engineers have made their influence felt on the world’s mercantile marine during the period of review, the collection by no means includes all who are deserving of such notice. The subjects of portraiture are all in life, and actively engaged in their respective spheres of labour. The diffidence generally evinced by them in consenting that their likenesses and the note of their professional career should be given, has made my task one of difficulty. What may be called the over-diffidence of a few, originally selected for portraiture, has to some extent occasioned the incompleteness now commented upon.

As further accounting for the limitations of the present work, I think it fitting to add that the preparation of the whole book, including the task of seeing it through the press, has devolved upon me at a time when the ordinary intervals of respite from daily business have had to suffice for its accomplishment.

My best thanks are due to those firms and individuals to whom I had to appeal for statistics and other particulars, for their generally ready and courteous attention to my requests.

DAVID POLLOCK.

Dumbarton, November, 1884.

| CHAPTER I. | |

| RECENT PROGRESS IN STEAMSHIP CONSTRUCTION. | |

| PAGE | |

| Growth in Dimensions of Steamships—America’s Place in Ocean Traffic—Shipbuilding in America—Wood versus Iron Shipbuilding—Introduction of Mild Steel for Shipbuilding—Suitability of Mild Steel for Shipbuilding—Economical Advantages of Steel Ships—Reduction in Cost of Mild Steel—Pioneer Steel Steamships—Cellular Bottom Steamships—Description of Cellular Bottom System—Adoption of Water Ballast—Spread of Cellular Bottom System—Cellular Bottom Sailing Ships—Minor Structural Modifications—Cast Steel Stern Frames, Rudders, &c.—Advantages of Cast Steel Stern Frames, Rudders, &c.—Probable Future of Steel Castings—List of Papers, &c., bearing on Ship Construction | 1 |

| CHAPTER II. | |

| SPEED AND POWER OF MODERN STEAMSHIPS. | |

| Early Atlantic Mail Steamers—Reduction of the Atlantic Passage-time—Modern Transatlantic Steamships—Fast Atlantic Passages—The Future of the Atlantic Service—Cape of Good Hope Mail Service—Employment of Steamers on Long Voyages—Australian Direct Steam Service—New Zealand Direct Steam Service—Increased Number of High-Speed Steamers—Economy in Coal Consumption—Construction of Modern Marine Boilers—Improved Boiler Fittings—Combustion by Forced Draught—Reduced Weight of Machinery—Triple Expansion Engines—Designs for “Ships of the Future”—The Future of Ship Propulsion—List of Papers bearing on Speed and Power of Steamships | 27 |

| CHAPTER III. | |

| SAFETY AND COMFORT OF MODERN STEAMSHIPS. | |

| Water-tight Sub-division—Value of Proper Sub-division—Dangers of Inefficient Sub-division—Merchant Steamers on Admiralty List—Safety due to Double Bottoms—Safety due to Employment of Steel—Safety as affected by Construction—Causes of Unseaworthiness—High Qualities of Ship Construction—Safety due to Articles of Outfit—Improved Nautical Instruments—Devices for Unsinkable Ships—Devices for Life-Saving—Comfort on Board Modern Steamships—Comfort as affecting Ship Design—Improved Saloon Accommodation—Electric Light on Board Ship—Electric Ship Signal Lights—Ventilation on Board Ship—Improved Systems of Ventilation—Hydraulic Appliances on Board Ship—The Bessemer Channel Steamer—The Causes and Alleviation of Sea Sickness—Progress due to Novelty in Design—List of Papers, &c., bearing on Safety and Comfort of Ships | 51 |

| CHAPTER IV. [vi] | |

| PROGRESS IN THE SCIENCE OF SHIPBUILDING. | |

| The Lessons of Disaster—Sources of Scientific Knowledge—Government Schools of Naval Architecture—Greenwich Royal Naval College—The Transition from Sail to Steam and from Wood to Iron in Shipbuilding—Labours of Russell, Rankine, and Froude—Institution of Naval Architects—Recent Scientific Progress—Outlines of Fundamental Principles—Shortened Methods of Ship Design—Metacentric Stability—Atwood’s Stability Theorem—Improvements of Atwood’s Method—Stability at Light-Draught—Stability Curves at Different Draughts—Cross-Curves of Stability—Stability Curves by Experiment—Stowage as affecting Stability—Speed and Power of Steamships—Approximating to Power Required—Progressive Speed Trials—Curves of Speed and Power, &c.—Speed Experiments with Models—Froude’s Law of Comparison—Relative Efficiency of Hull, Engines, and Propellers—Investigations of Strength of Iron Vessels—Reed’s and John’s Investigations—Strength Investigations as Affecting Registry Rules—Agencies for Scientific Education—University Chairs of Naval Architecture—List of Papers on the Science of Shipbuilding | 84 |

| CHAPTER V. | |

| PROGRESS IN METHODS OF SHIPYARD WORK. | |

| Piece-work System in Shipyards—Increased Use of Machinery—Powerful Punching Machines—Hydraulic Power Machines—Portable Hydraulic Riveters—Machine Riveting of Shell Plating—Hydraulic Riveting of Deck Work—Hydraulic Riveting of Beams and Frames—Hydraulic Riveting of Cellular Bottom Work—Hydraulic Riveting of Keels—Improved Wood-Working Machinery—Awards to Workmen for Improvements—Lifting Appliances for Heavy Weights—Improved Means of Transport in Shipyards—List of Papers bearing on Modern Shipyard Machine Tools, Appliances, and Methods of Work | 129 |

| CHAPTER VI. | |

| DESCRIPTIONS OF SOME NOTABLE SHIPYARDS. | |

| Messrs J. Elder & Co.’s Shipbuilding and Marine Engineering Works—Messrs Denny & Bros.’ Shipbuilding Works—Messrs J. & G. Thomson’s Shipbuilding and Engineering Works—Palmer Shipbuilding and Iron Company’s Works—Sir W. G. Armstrong, Mitchell & Co.’s Works—Mr Laing’s Deptford Shipbuilding Works—The Works of the Barrow Shipbuilding Company—Relative Output of Tonnage by the largest Firms | 150 |

| CHAPTER VII. | |

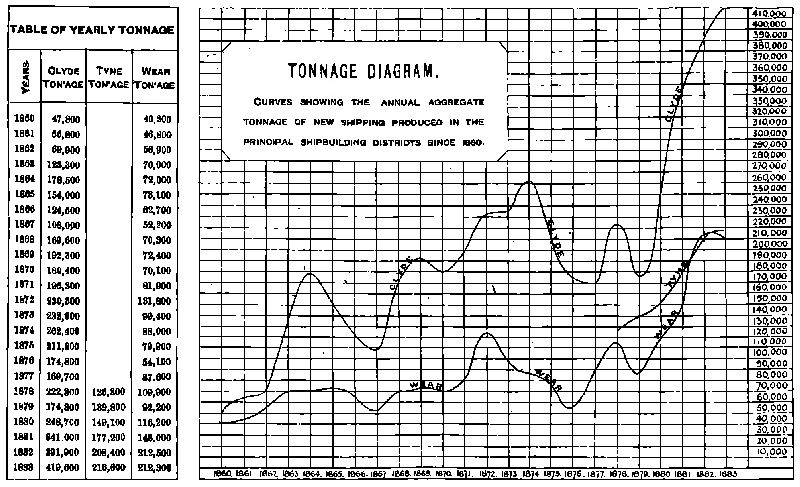

| OUTPUT OF TONNAGE IN THE PRINCIPAL DISTRICTS. | |

| Inaccuracy of Tonnage Statistics—Curves of Tonnage Output—Output in the Clyde District—Output in the Tyne District—Output in the Wear District—Relative Output in Principal Districts—Statistics of Steel Tonnage | 184 |

| CHAPTER VIII. [vii] | |

| THE PRODUCTION OF LARGE STEAMSHIPS. | |

| List of Vessels over 4000 Tons Presently or at one time Afloat—The Years in which the Production of Large Steamships have been Greatest—The Individual Share of the several Districts in Producing Large Steamships | 198 |

| APPENDIX. | |

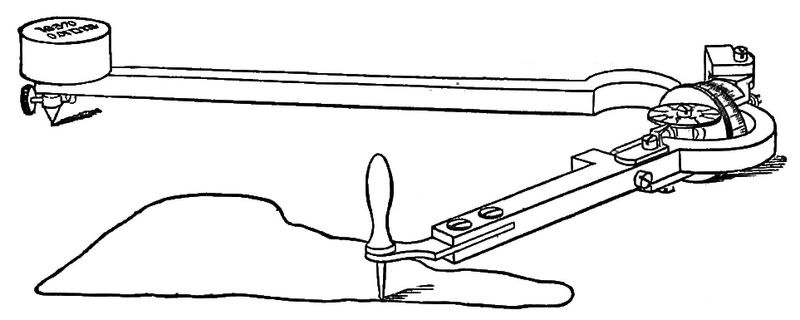

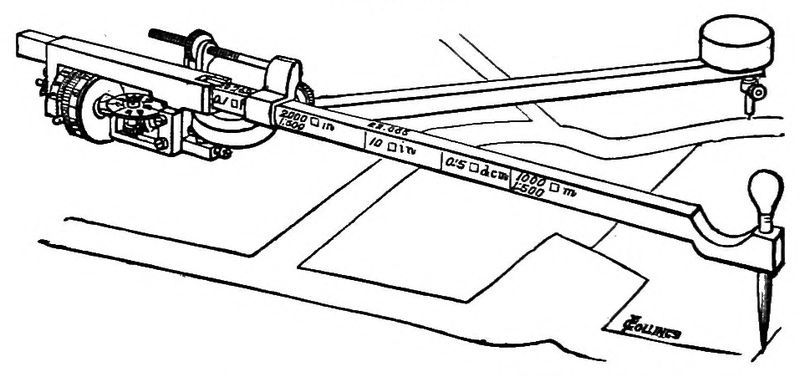

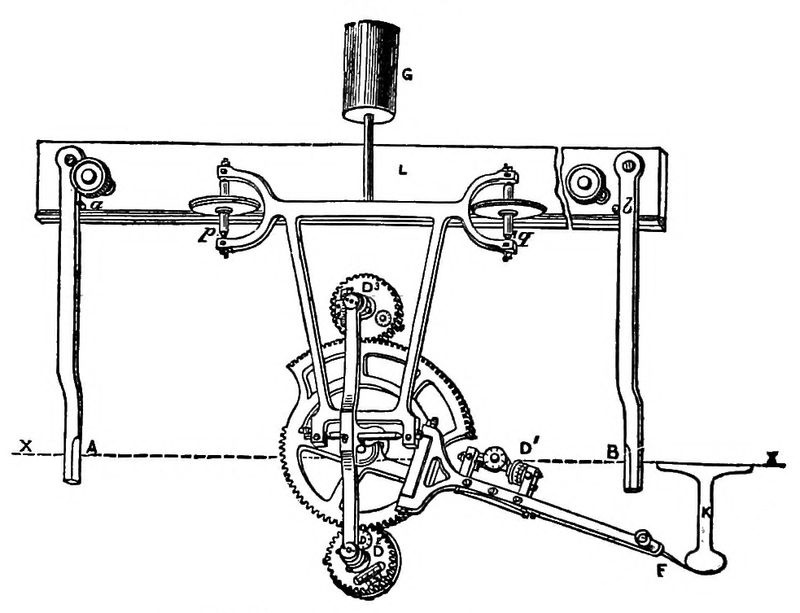

| CALCULATING INSTRUMENTS. | |

| Fuller’s Spiral Slide rule—Amsler’s Polar Fixed-scale Planimeter—Amsler’s Proportional or Variable-scale Planimeter—Amsler’s Mechanical Integrator | 207 |

| John Burns, | facing | Page | 2 |

| Nathaniel Dunlop, | ” | ” | 12 |

| Thomas Henderson, | ” | ” | 20 |

| William Pearce, | ” | ” | 30 |

| James Anderson, | ” | ” | 36 |

| Alexander C. Kirk, | ” | ” | 44 |

| Benjamin Martell, | ” | ” | 60 |

| William H. White, | ” | ” | 86 |

| John Inglis, Jun., | ” | ” | 106 |

| Sir Edward J. Reed, | ” | ” | 108 |

| Prof. Francis Elgar, | ” | ” | 114 |

| William Denny, | ” | ” | 118 |

| William John, | ” | ” | 124 |

| Charles Mark Palmer, | ” | ” | 172 |

| James Laing, | ” | ” | 178 |

VIEWS OF NOTABLE STEAMSHIPS.

| S.S. “City of Rome,” | Anchor Line, | Frontispiece. | |

| S.S. “Umbria,” | Cunard Line, | facing Page | 6 |

| S.S. “Austral,” | Anchor Line, | ” ” | 36 |

ERRATA.

“Into a ship of the line man has put as much of his human patience, common sense, forethought, experimental philosophy, self-control habits of order and obedience, thoroughly wrought handwork, defiance of brute elements, careless courage, careful patriotism, and calm expectation of the judgment of God, as can well be put into a space 300 feet long; by 80 feet broad.”—Ruskin.

“If any body of men have just cause to feel pride in their calling, and in the fruits of their labour, shipbuilders have. If we look at the magnitude of the operations of building, launching, engining, and completing a modern passenger ship of the first rank, and regard the multiplicity of the arrangements and beauty of finish now expected, and then think this structure has to brave the elements, make regular passages, convey thousands of human souls, and tens of thousands of tons of merchandise every year across the ocean, in storm or calm, we cannot but feel that they are occupied in useful human labour. But more than this, there is a public sentiment surrounding ships that no other mechanical structures can command. Beautiful churches, grand buildings, huge structures of all kinds have a certain interest pertaining to them, but it is different in kind from that which surrounds a ship. The former are fixed, immovable, inert; the ship is here to-day and gone to-morrow, building up a history from day to day with a reputation as sensitive as a woman’s to calumny, and like her consequently often a bone of contention as well as an object of admiration.”—William John.

MODERN SHIPBUILDING.

The achievements in shipbuilding and marine engineering within recent years may be said to borrow lustre from one particular feat of past times. The Great Eastern undoubtedly furnished, in large measure, the experience that has recently been causing so great a change in the tonnage of our mercantile marine. Commercially, as is well known, that huge vessel—“Brunel’s grand audacity,” she has been called—has all along proved a lamentable failure. It has been stated on good authority that between 1853—the year in which the contract for her was entered into—and the year 1869, no less than one million sterling had been lost upon her by the various proprietors attempting to work her. Financially, indeed, she may be said to have proved the “Devastation” of the mercantile marine. Although at various times in her long life-time she has unquestionably done most useful service in sub-marine cable-laying—service, indeed, which, but for her, could not well have been accomplished—these times of usefulness have been far outbalanced by her long periods of inactivity.

Apart from commercial considerations, however, this premier leviathan still stands out as a wonder and pattern of naval construction. In her admirably-conceived and splendidly-wrought structural arrangements—due to the joint labours of the late Mr I. K. Brunel and Mr J. Scott Russell—she possesses as successful an embodiment of the dual quality of “strength-with-lightness” as can be found in any subsequent ocean-going merchant ship. She was, if not the first, certainly the greatest embodiment of the longitudinal system of construction, and in virtue of this, as well as of her phenomenal[2] proportions, she represents, alone, more of the intrepidity and skill essential to thorough progress, than are exhibited by combined hosts of the “departures” of recent times.

Despite the far-reaching views of the eminent designer, those changes which have since taken place in the essential conditions for successful ocean navigation eluded his vision. Owing to the opening of coal mines in almost all parts of the world, it is now no longer necessary nor desirable that a steamer should be capable of carrying coals for a return voyage, either from India or Australia—this being the dominant and regulating condition in the Great Eastern’s design. Further, the improvements in marine engineering, represented by the greater possible economies in coal consumption and the fuller utilization of steam, which have since been effected, have rendered the great ship inefficient and obsolete. In short, Brunel and his financial supporters were ahead of their time, and failed to appreciate the law of progress, now better understood—“invention must wait on experience.”

The urgent demands of our broader civilisation, improvements in navigation, the spread of population in new colonies and over wider continents, and, above all, the fresh accessions of experience and invention, are forces which now impel shipowners to increase the dimensions of their vessels, and shipbuilders to carry out the work. Each year the contrasts as to dimensions between the first leviathan and her later sister grow less and less. The completion within the past few years of such monster merchant ships as the Servia, the City of Rome, the Alaska, and the Oregon, and the forward state of the Etruria and Umbria, two remarkable steamships, building on the Clyde for the Cunard Company, constitute an epoch in the history of our mercantile marine, and give colourable justification to the belief sometimes expressed, that the proportions of the Great Eastern will in time be surpassed.

The feasibility—in a scientific sense—of ships growing in proportions commensurate with the growth of commerce and traffic, has often been commented upon. The whole tendency of our time is towards the aggregation of effort: the massing of[3] capital and labour. A vessel of five thousand tons can be built cheaper than five vessels of one thousand tons. In the manning and working of ships there is a still more striking economy, e.g., one captain instead of five, and so on throughout the staff of officers, engineers, stewards, and crew. Not only so, but long ships can be propelled at greater speeds than short ones, the whole conditions of construction, engines, and propellers being considered. Mr Robert Duncan, in his presidential address before the Society of Engineers and Shipbuilders in Glasgow in 1872, declared:—“Looking forward one generation, and measuring the future by the past, I think it is not problematical that we shall see steamers of eight hundred feet long the ferryboats of two oceans, with America for their central station, and Europe and Asia for their working termini.” Even since that was uttered, eleven years ago, we have approached, in solid practice, the limit thus laid down, by 150 feet at least. Three years previous to Mr Duncan’s address, vessels exceeding four hundred feet were not afloat, with the notable exception already referred to; now, there are few merchant fleets of any pretensions engaged in ocean traffic which do not include vessels over or approaching four hundred feet, and it is even no great boast that vessels close on six hundred feet are afloat and in active service.

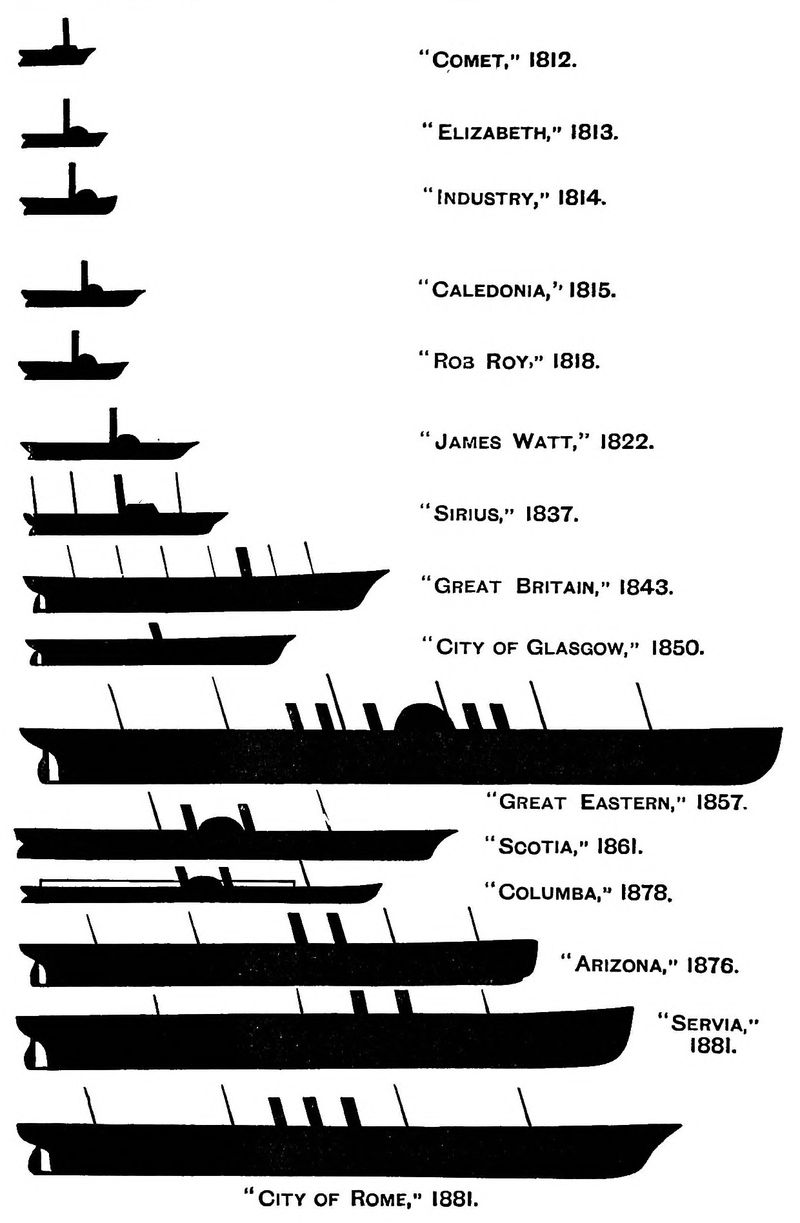

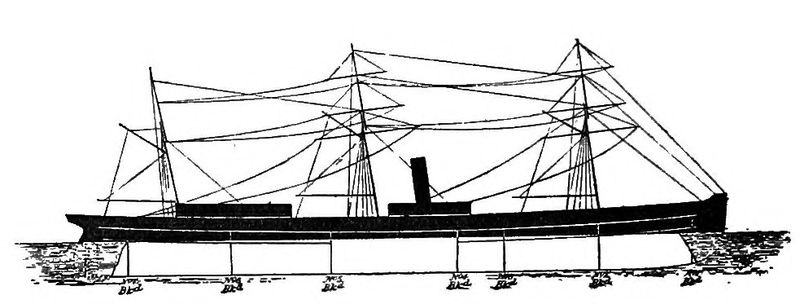

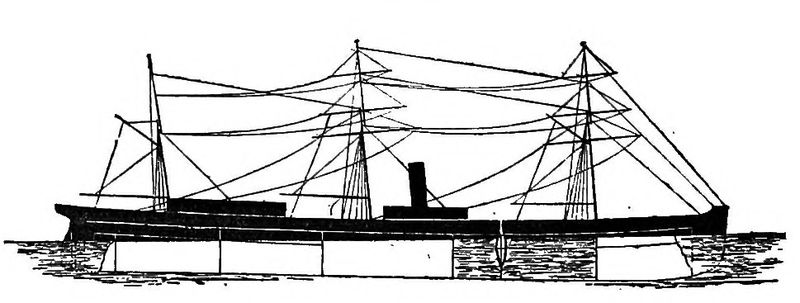

As better illustrating the growth in dimensions of merchant steamships, the Figs. on the following page may prove interesting. They show, all to the same scale, a number of representative steam vessels from the Comet downwards.

“Comet,” 1812.

“Elizabeth,” 1813.

“Industry,” 1814.

“Caledonia,” 1815.

“Rob Roy,” 1818.

“James Watt,” 1822.

“Sirius,” 1837.

“Great Britain,” 1843.

“City of Glasgow,” 1850.

“Great Eastern,” 1857.

“Scotia,” 1861.

“Columba,” 1878.

“Arizona,” 1876.

“Servia,” 1881.

“City of Rome,” 1881.

Along with the change or evolution in the sizes and types of merchant vessels, important modifications in their structural arrangement have of late years been effected, and it is to the constant progress being made in these matters—to the skill and intrepidity which are brought to bear on their execution, and to the readiness with which our shipowners recognise their importance and value—that the maintenance of our mercantile supremacy is largely owing. An American[5] journal, writing a few years ago on this subject—perhaps with more of taunt for the conceit and self-sufficiency evinced by its own country than of adulation for the ability and enterprise displayed by ours—said:—

“In the whole world there is no place whatever that can in any degree compare with the Clyde for either extent or quality of steamship building; and at this moment an indisputable verification can be adduced, for between American and European ports there are at the present time something like a score of steam navigation companies, doing an immense passenger and carrying trade, with vessels of great power and magnificence, and notwithstanding the variety of trade nationalities, at least two-thirds of the vessels employed were built and equipped on the Clyde; and more—unless there has very recently been a change, there is not an American steam company in the whole Atlantic trade. With a run of about fifty years to try it, and after many unsuccessful attempts, the Americans have utterly failed to sustain permanent competition. All the British companies have prospered beyond any probable anticipation clothed with reason. The Cunard Company, starting with four vessels some forty years ago, have now twenty times that number. What is this something which enables Europeans to so far outstrip the Americans in a competitive traffic so as to exclude them from the merest show in the largest steam trade in the world? A baneful, overweening, and ignorantly selfish conceit invariably leads to disastrous results, and a nation given over to the fulmination of concentrated boast cannot fail to be suffocated with foolery of its own making.”

This is doubtless the outcome of a vicious antipathy—natural in the circumstances—to those stringent and over-reaching laws which forbid that ships built away from America shall sail under the American flag, or enjoy the pertaining privileges. American shipbuilders thus secured from the encroaches of foreign competition, have enjoyed their own pace, but at too great a sacrifice. Preferring to take the material most at hand, the manipulation of which they well understood, they have allowed their wood age to be dove-tailed thirty years into our iron one, with the other result that America now occupies as unimportant a place in the traffic of the sea, as the above quotation indicates.

Evidences are not wanting, however, to show that America is at least endeavouring, in some respects, to be abreast of the times, and that she has brought herself to acknowledge and follow the lead of this country. In this connection, the four[6] new vessels presently being constructed for the U.S. Navy may be shortly referred to. The vessels comprise three cruisers and one despatch boat, all of which are being built by Mr John Roach, of Chester, Pa., the material employed in their construction being mild steel of American manufacture. Twin screws will be employed for the propulsion of the largest vessel—the Chicago—which is to be 315 feet long between perpendiculars, 48 feet beam, and 34 feet 9 inches moulded depth to spar deck. The other vessels are the Boston and the Atalanta, single screw cruisers of 270 feet length; and the Dolphin, single screw despatch boat, of 250 feet length and high speed.

In almost every feature except machinery these new American naval vessels strongly resemble Government vessels of recent British build, a circumstance for which there is little difficulty in accounting, as it is well known the naval authorities in the States have within recent times been recruited by young American naval architects educated in our Naval College at Greenwich, and consequently steeped in British naval practice. This and other facts, such as the visit of a technical commissioner of the States’ navy, two years ago, to our naval and mercantile shipyards—upon which he has since fully reported—leave one in no doubt as to the source of coincidence in design and structure.

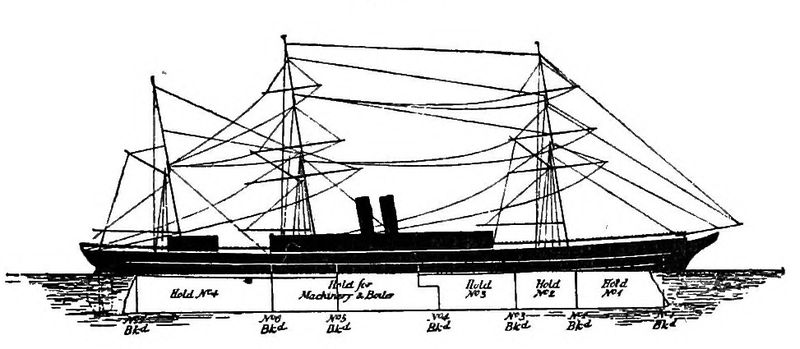

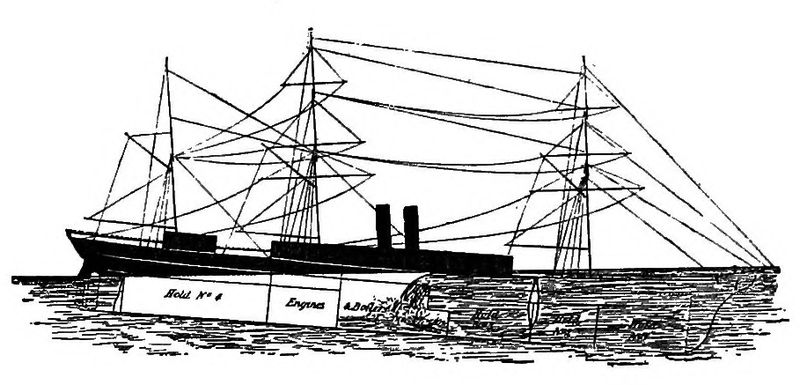

| Length, | 500 ft. 0 in. | Depth, | 40 ft. 0 in. |

| Breadth, | 57 ft. 0 in. | Tonnage (Gross), | 7,718 tons. |

| Built by Messrs Elder & Co., 1884. | |||

The subject of America’s position as a shipbuilding and shipowning country has involved reference to wood shipbuilding, but to revert at any length to this topic in a work dealing with modern progress in British shipbuilding, the bulk of which is written of and for industrial and commercial centres where wood shipbuilding has been long entirely tabooed, is quite unnecessary. Doubtless, however, the amount of wood and composite building still carried on in the minor seaports of the United Kingdom, and in several of the British possessions, is of sufficient importance to demand some reference. As the present position of affairs in this connection[7] is briefly and forcibly illustrated by statistics compiled and issued by the British Iron Trade Association, two tables taken from this source may be given, the subject thereafter being finally departed from:—

Tonnage of Vessels constructed and registered in the United Kingdom of Iron, Steel, and Wood respectively, in each of the years 1879 to 1883, with Percentage of Total Tonnage constructed in Iron and Steel.

| Year. | Gross Tonnage of Vessels built of | ||

|---|---|---|---|

| Iron and Steel. | Wood. | Excess Tonnage in Iron and Steel. |

|

| 1879 | 484,636 | 26,186 | 458,450 |

| 1880 | 525,568 | 19,938 | 505,630 |

| 1881 | 730,686 | 18,107 | 712,579 |

| 1882 | 913,519 | 14,850 | 898,669 |

| 1883 | 1,012,735 | 15,202 | 997,533 |

| Totals, | 3,667,144 | 94,283 | 3,572,861 |

Tonnage of Wooden Vessels registered in the United Kingdom which were Lost, Broken up, &c., during each of the years 1879 to 1883, with Tonnage of Wooden Vessels built and registered in the United Kingdom during the same period.

| Year. | Tonnage of Wooden Vessels. | Excess of Vessels lost over those built. |

|

|---|---|---|---|

| Lost. | Built. | ||

| 1879 | 149,828 | 26,186 | 123,642 |

| 1880 | 173,065 | 19,938 | 153,127 |

| 1881 | 170,283 | 18,107 | 152,176 |

| 1882 | 166,809 | 14,850 | 151,959 |

| 1883 | 144,138 | 15,202 | 128,936 |

| Totals, | 804,123 | 94,283 | 709,840 |

Whence it appears that while 709,840 tons of the 1,779,112 tons of ships removed from the register during the last five years were wooden vessels, only 94,283 tons of the 3,667,144 tons built and registered in the United Kingdom during the same period were constructed of that material. In other words, wooden ships represent 45 per cent. of the total losses, while they only represent 2·5 per cent. of the total tonnage built and added to the register during the five years in question.

Just as the introduction or general adoption of the compound engine marked an epoch in the history of shipbuilding and marine propulsion, so now the introduction of “mild[8] steel” or “ingot iron” as a material for shipbuilding, together with the more extended adoption of water ballast, and the rapid development of the continuous-cellular system of construction, may be said to constitute a fresh starting point in the history of the industry.

Although the introduction of steel as a material for shipbuilding dates at least as far back as 1860, its use has been but partial or occasional until within very recent times. The uncertainty as to quality, the frequent great disparity between pieces cut from the same plate, and the special care needed in the manipulation, prevented its general adoption. With the highly-improved “mild steel,” however, first manufactured in France, and applied to shipbuilding purposes there about nine years ago, and subsequently introduced into this country, began the more extended adoption of steel, which every day, or with every accession to experience, is displacing iron.

The facts relating to the introduction into this country of mild steel for shipbuilding purposes, may be briefly recounted. In the latter end of 1874, Admiral Sir W. Houston Stewart, Controller of the British Navy, and Mr N. Barnaby, Director of Naval Construction, availed themselves of the opportunity to observe and study the use of steel in the French dockyards of Lorient and Brest, where three first-class armour-plated vessels were then being built of steel throughout, supplied from the works at Creusot and Terrenoire. Mr Barnaby, at the meetings of the Institution of Naval Architects in March following, gave an account of his observations during this visit, and pointed out clearly and precisely to the steel-makers of Great Britain all the indispensable conditions which would have to be met and satisfied by steel for shipbuilding, so that it could be used with confidence in the construction of the largest vessels. Before the end of 1875, the Landore-Siemens Company was enabled to fulfil these conditions, and the Admiralty contracted with them to supply the plates and angles necessary for the construction of two cruisers of high speed—the Iris and the Mercury. The material involved in this contract was steel obtained by the Siemens-Martin process.[9] Shortly after this the Bolton Steel Company was in its turn able to produce by the Bessemer process plates and angles, satisfying all the requisite conditions. The Steel Company of Scotland, Butterly Company, and other important works, also entered into the same business, and operations are still going on in various parts of the country connected with the formation of new works, and the perfecting of other processes.

The steel furnished by these different works, subjected as it has been to systematic and severe tests continually applied, is now possessed of the qualities of ductility, malleability, and homogeneity, which render its employment in shipbuilding not only permissible but highly desirable. Its good and reliable qualities have been admitted by the Constructors of the Navy, the Officers of the Board of Trade, of Lloyd’s, and of the Liverpool Registries, as well as by all the most competent authorities. The experience of all who have practical dealings with the material in the shipyard is that it entirely satisfies—even more than iron—all the requirements of easy manipulation. The confidence with which it can be relied on, as to its certain and uniform qualities, places it on a much higher level than the steel formerly manufactured; and its superiority over the best wrought-iron as regards strength and ductility renders it a highly preferable material.

While doubt exists, however, as to the adoption of steel for shipbuilding being commercially advantageous; there must be hesitancy on the part of shipowners and others concerned. Although, since its introduction, mild steel has been greatly reduced in price, the first cost of a steel ship is still somewhat over that of an iron one, even after the reduction in weight of material is made, which the superiority of steel permits of. It has been shown that, about two years ago, a spar-decked steamer, of 4,000 tons gross, built in steel, as against a similar vessel built in iron, entailed an excess in cost of £3,570. The advantages, however, which accrue from the change, both immediate and in the long run, make the gain clear and considerable. Steel ships have been built with scantlings reduced one-fourth or one-third, and in some early cases even one-half,[10] from what would have been considered requisite had iron been employed. Some authorities, not unnaturally, questioned the wisdom of accrediting steel with all the qualities which make such sweeping reductions justifiable. Except in vessels for river or passenger service, however, this is much in advance of the reductions obtained in ordinary modern practice.

The reductions allowed in vessels built to Lloyd’s requirements—and it cannot be urged that this society is too reckless in concessions of this nature—are 20 per cent. in scantling, and 18 per cent. in weight. As it is impossible to adjust the scantlings of material to take the full advantage of these reductions, and further, as allowance has to be made for extra weight due to the continued use of iron in vessels of steel—for purposes not essential to structural character—the average weight-saving effected in practice is about 13 to 14 per cent. This represents, in the finished vessel, a clear increase of at least 13 per cent. in dead-weight carrying power. The gain obtained in general practice has been otherwise stated on good authority as 7 to 7½ per cent. of the gross tonnage.

In trades where there is constancy of dead-weight cargoes, this increase in dead-weight carrying power should speedily recoup the owners for extra first cost, and in the life-time of vessels generally, a clear pecuniary gain should result. In trades, however, where the cargo consists of measurement goods, the advantages are not so decided, for it may sometimes happen that before vessels have been loaded to their maximum draught the limits of stowage will have been reached. Even here, however, the steel vessel has the advantage of her iron rival; her hull is 13 per cent. lighter, and consequently may be propelled at a given speed with much less expenditure of power, and has the further advantage—often a very important one—of a shallower draught. This latter consideration alone, in a service where every iota of such saving counts, has influenced many shipowners to adopt the steel.

As the manufacture of mild steel progresses and extends, the assimilation of the rival materials as to cost is sure to follow. Already very great advances have been made towards[11] this end, the fact being abundantly evidenced by the greatly increased number of steel ships on hand, and by the establishment of new works, and transformation of old, for the better production of the new material. In 1877 mild steel was about twice as costly as the iron in common use. The sources of supply, however, were then comparatively few, and the thorough and severe testing to which the new material had to be subjected, necessarily increased the cost relatively to iron, which has never been subjected to the same rigorous ordeal. In 1880, owing to the increased sources of supply and the progress in manufacture, the cost of steel had been reduced, relatively to iron, by about 50 per cent. At the time of writing (March, 1884), the price of steel for a good-sized vessel is—overhead—about seven pounds, seven shillings and sixpence per ton; while the corresponding figure for iron is about five pounds, five shillings, or a difference of only about twenty-nine per cent. in favour of the older material.

Doubts were at first expressed by not a few, regarding the durability of steel ships compared with those of iron, such misgivings being aggravated by the thinness of the steel plating. This fear is being gradually lessened by the results of laboratory experiments and bona fide experience—the broad deduction from which is, that the deterioration of steel, under the action of sea water, is no greater than that of iron, and that, if the same care and constancy in cleaning and painting, common to ships of the latter material, be extended to ships of the former, their durability will be equal.

Several large shipowning companies were not slow to place faith in the new material. In the early part of 1879, the “Allan Line” Company entrusted to Messrs Denny & Brothers, of Dumbarton, the order for a huge vessel, which the intrepid confidence of the principal partners in both the owning and the building firms determined should be of mild steel, be bound with steel rivets, and have her boilers of the same material. This was the large steamer Buenos Ayrean, the first transatlantic steamer built with the new material. She was finished early in 1880, and had not been over nine months in[12] the water when the order for a second and still larger steel vessel—the Parisian—had been given by the same owners to Clyde builders. The Union Steamship Company of New Zealand, the Pacific Steam Navigation Company, Messrs Donald Currie & Co., and several smaller companies, ordered vessels of steel almost simultaneously, while yet the new material was in the early stage of trial. Amongst the orders for steel vessels which were subsequently given, the Servia and Catalonia, for the Cunard Company; the Clyde and Thames and Shannon for the Peninsular and Oriental Company; the India, for the British India Company; the Arabic and Coptic, for the Oceanic Steam Navigation Company, and the four twin screw steamers of the “Hill” Line, represent the principals. The companies who then adopted the new material have mostly continued to have their new ships built of steel, and to name the vessels since built and now building in which this material is employed, would simply be to enumerate three-fourths the fleet of high-class modern merchant ships. There were 21,000 tons of steel shipping built throughout the United Kingdom in 1879; 36,000 in 1880; 55,000 in 1881; 126,000 in 1882; and over 244,000 in 1883. It is computed that at the present time the amount of steel shipbuilding going on throughout the kingdom is not less than 175,000 tons, or the largest amount on hand at any one time since its introduction.

The modification in the structural arrangement of ocean trading vessels, already spoken of as the continuous-cellular system, although only within very recent times receiving extended adoption in the mercantile marine, possesses in some of its essential features the prestige of years. So long ago as 1854, Mr Scott Russell strongly advocated the principle of longitudinal construction, and applied it in practice to ships of the mercantile marine, to the success of which, in a scientific sense, the Great Eastern is surely overwhelming testimony. The principle met with much scientific favour from many besides Mr Russell, but it did not take root in solid practice.[13] Pecuniary and other kinds of considerations interposed to prevent its general adoption. The urgency for increase in the size of vessels was not such as to make longitudinal strength (the special advantage claimed for the new principle) a great desideratum; and there was perhaps reluctance on the part of shipbuilders to relinquish time-tried and familiar methods. The system presently under notice—although, as has already been said, the same, in its main principles, as the system then advocated—by its descent through the Admiralty Dockyards, by its application to merchant vessels—first of East Coast, and then of Clyde build—and by its close association with water ballast, has undergone many modifications which almost constitute it a creation of recent times.

Sir Edward J. Reed, when Chief Constructor of the Navy, introduced the bracket frame system of construction into iron-clad ships of war, and, as already indicated, it is largely owing to the experience of the system as applied and practised in such cases—conjointly, of course, with its successful introduction in the case of the Great Eastern—that in so short a time it has reached the present structural perfection, and received such wide extension in merchant steamships. That it has recently received such wide adoption in the mercantile marine is due not so much to its structural advantages—and these are great—as to the way in which it lends itself to the economical working of steamships in actual service. This will be more explicitly referred to after some description of the system as applied in merchant ships has been given.

It is somewhat away from the field this work is concerned with, to trace the system in its stages of development in ships of war, but it may be said, shortly, that the impulse which the system has received in the mercantile marine has in no sense been a transference of the activity which at all times since its introduction has characterised the application of the system to the vessels built in our naval yards.

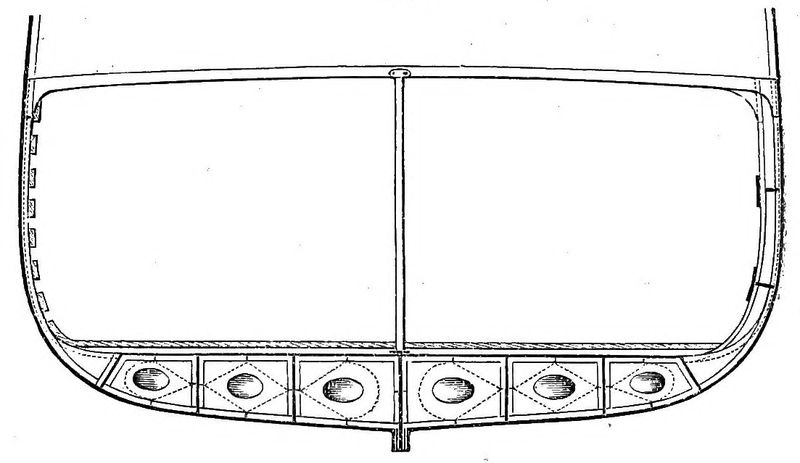

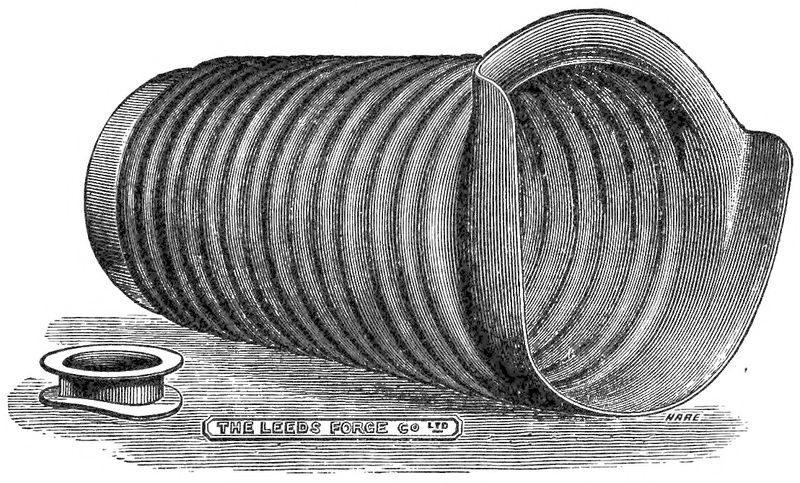

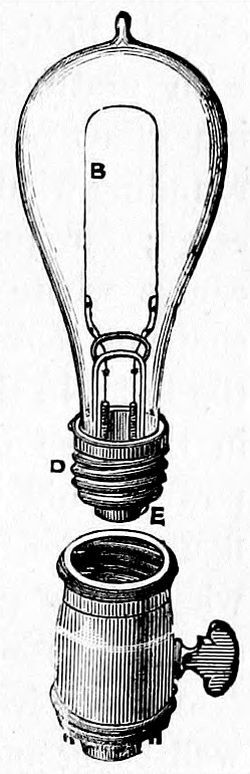

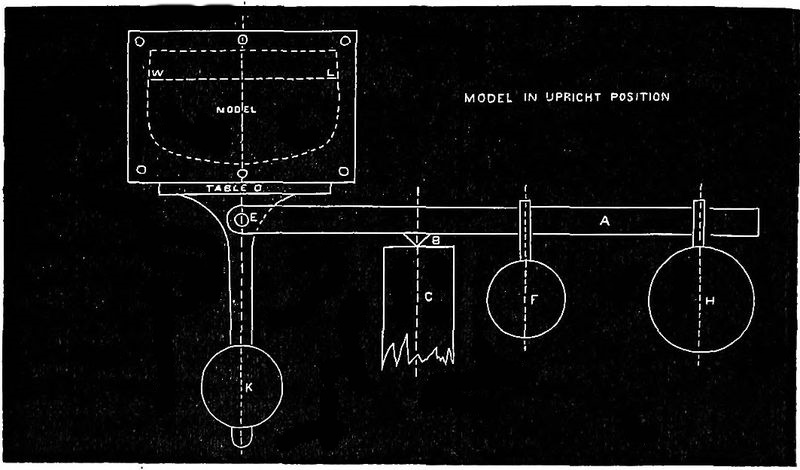

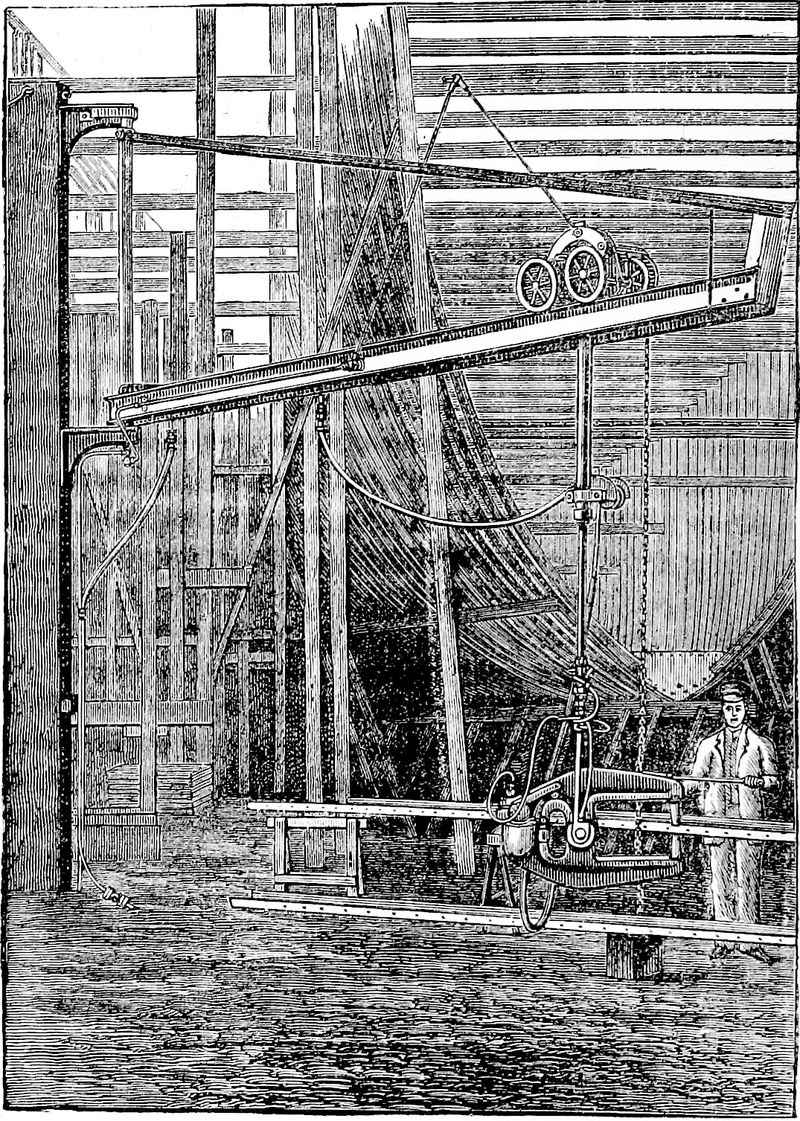

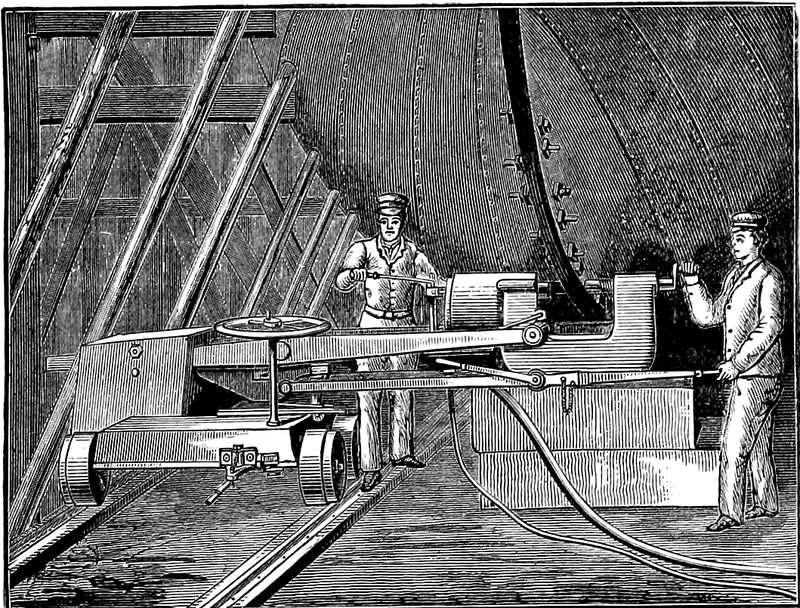

In order to assist the non-technical reader in appreciating what follows regarding the system in merchant ships, a[14] general idea of the cellular bottom principle of construction is afforded by Fig. 1.

This shows in section the bottom part of a vessel amidships, fitted with a double or inner skin, extending across the ship from bilge to bilge, and there connected in a watertight manner to the outer bottom plating. A series of longitudinal plates are worked, fore and aft; set vertically between the outer skin of the vessel and the plating of the inner bottom, and connected thereto by continuous angles. Between these “longitudinals,” and at every alternate transverse frame, deep plate floors, lightened with oval holes, are fitted, connected to outer skin by the angle frame, and to inner bottom plating by pieces of angles corresponding to the vessel’s “reverse frames.” These floor plates are, in addition, connected by vertical angles to the longitudinals. Intermediate between the deep plate floors simple angle bar transverse frames and reverse frames are fitted, to give support to the outer skin and to the inner bottom respectively. Until recently, the deep floors consisted of “gusset” or “bracket” plates, each division being fitted in four separate pieces, the whole taking the form as shown in dotted outline. This practice is still most largely followed, but in those yards which are equipped with large hydraulic[15] punching machines for piercing holes such as are shown in Fig. 1, the solid floors have superseded the bracket or four-piece floors, the change effecting a simplification of work and decided structural advantages.

With the employment of water as a substitute for dry or rubble ballast, the structural movement under notice may be said primarily to have begun. This movement has resulted in the present approved system, which, at the same time that it has regard to water-ballast with all its attendant advantages, most happily combines the important qualities of increased strength and security. The need for ballast in vessels whose service generally comprises “light” as well as “loaded” runs (as in the coal trade between Newcastle and London), or in trades where the full complement can only be obtained by shifting from port to port, is obviously great. It is doubtless to needs such as these, more than to any demand for increased structural strength, that the introduction and extended application of the longitudinal and bracket-plate principle is owing.

The screw-steamer Sentinel, built in 1860 by Messrs Palmer of Jarrow, Newcastle-on-Tyne, is mentioned by some authorities as embodying some of the main features of the longitudinal and cellular bottom system, and the screw-steamers Scio and Assyria, of 1440 tons, built in 1874 by Messrs Westerman, near Genoa, have been noticed in a similar connection. The next vessel, in point of time, which contained features answering to the system now in vogue, and from the date of whose production the movement has been almost constantly progressive, was the screw-steamer Fenton, built by Messrs Austin & Hunter, of Sunderland, in 1876.

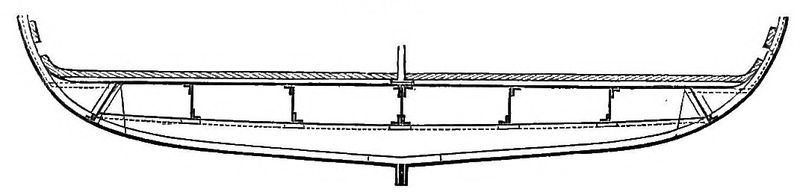

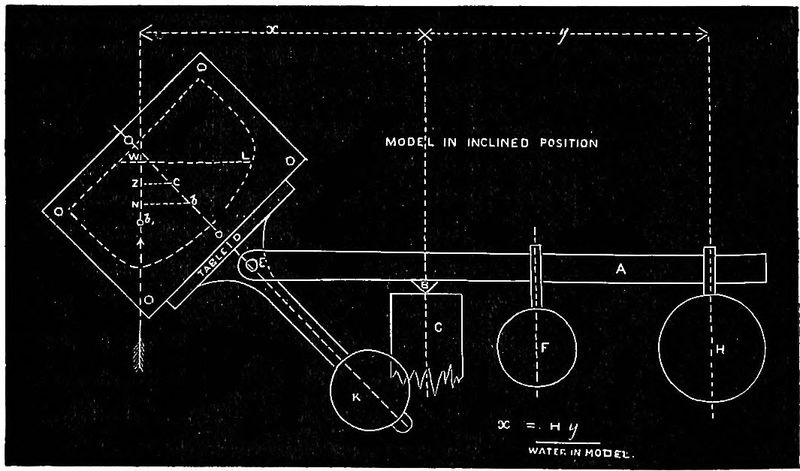

Clyde builders were not slow to recognise the value of the system in its application to water-ballast steamers, and almost immediately some of the more intrepid of their number began to advocate its adoption, but with some modifications, in vessels then being contracted for. Mr John Inglis, jun., of Messrs A. & J. Inglis, Pointhouse, Glasgow, submitted to Lloyd’s Registry in March, 1878, the scantling section of some cellular bottom vessels, then in project, which contained several of the[16] improvements introduced in subsequent practice. Messrs William Denny & Brothers, of Dumbarton, at the same time took up the principle, and have since actively applied it to steamers of every character in which water-ballast is a desideratum. Adopting it, five years ago, in four sister vessels for the British India Steam Navigation Coy., they subsequently raised the important issue with the Board of Trade regarding the tonnage measurement of these vessels. This august body insisted on computing the register tonnage—the figure upon which the tonnage dues are levied—not to the top of the inner bottom, but to an imaginary line half-way down the cellular space—in fact, to where the line of floor would have been if constructed in the ordinary fashion. Messrs Denny maintained, in effect, that as the register tonnage was meant to be a measure of the space available for cargo, the top of the ceiling on the inner bottom was the only equitable line of measurement. The principal reason for the Board seeking to pursue this course seems to have lain in the supposition that owners would endeavour to use the double bottom for cargo-carrying purposes. An ambiguity in the words of the Merchant Shipping Act, or their inapplicability to present day practice, were other possible elements in the case, but doubtless the red-tapeism and self-sufficiency characteristic of the Board had much to do with their action. This is borne out by the fact that although the Messrs Denny succeeded in their plea with respect to vessels having structural cellular bottoms, the absurd practice is still followed in cases where the bottom is fitted for water ballast on the girder principle, i.e.—the inner bottom fitted upon fore and aft runners or girders, erected on floors of the ordinary description, as shown in Fig. 2.

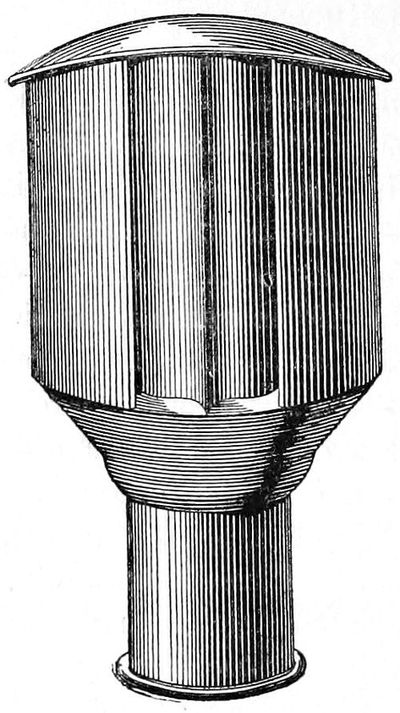

This formed, and still forms in many places, a very common arrangement for water ballast steamers, although not so inherent a feature of the vessel’s structure as the continuous-cellular bottom. In most cases this system is fitted only for part of the length, and not, like the cellular system, applied throughout the whole length of the ship. If it was impossible for the Board of Trade to hold by the contention that cargo might be carried in bottoms of the structural cellular type, it is equally untenable in the case of bottoms such as are now referred to. The difference between the two kinds of ballast bottoms is one merely of construction, and if any one of the two lends itself to cargo-carrying purposes, it is certainly the cellular system. The anomaly is sufficiently striking to merit attention, and in certain districts where the girder system is largely adopted for medium-sized vessels, it is felt as nothing short of an injustice, both by shipowners and builders.

The concession or victory won by Messrs Denny removed a serious hindrance to the spread and general adoption of the water ballast cellular system. Other Clyde firms at the same time—or at least soon after the adoption of the system by the Messrs Denny—took the matter up and independently did much towards the popularisation of the cellular mode of construction. Speaking in the early part of 1880, Mr William John, of Lloyd’s Registry, now General Manager with the Barrow Shipbuilding Company, said:—“At the time Mr Martell read his paper on water-ballast steamers before the autumn meeting of this Institution (Naval Architects) at Glasgow, in 1877, there had been only two or three small steamers built (since Mr Scott Russell’s early ones) on the longitudinal principle. Now, it is within the mark to say there are one hundred steamers, built and building, whose bottoms are constructed on the longitudinal principle, or what is better described as the cellular system, amounting probably to 200,000 tons, and it is not outside the bounds of probability that a very few years will see the majority of merchant steamers constructed in this manner.” Mr John’s connection with Lloyd’s at the time, entitled his statements and opinions[18] with regard to the prevalency and prospects of cellular construction to be accepted with every assurance, for it is in such Societies as Lloyd’s where the best consensus of information regarding the extent and tendencies of particular types of vessels can be obtained. In point of fact, the intervening period has witnessed, in great measure, a realisation of Mr John’s forecast. The advantages of a cellular bottom as regards safety, and for the purpose of ballasting and trimming vessels, also as meeting the greater need for longitudinal strength caused by the enormous growth in the size of vessels, have received that appreciation from shipowners and shipbuilders which is their due. The practice has accordingly spread, till now, it would not be rash to say, quite as many of the ocean-trading steamers being built are fitted with cellular bottoms as are without them.

The adaptation of water ballast to sailing vessels, as well as to steamers, has received consideration at the hands of both Tyne and Clyde builders. Previous to 1877, several small sailing ships were built on the Tyne, in which provision was made for water ballast in tanks entering into the structure of the bottom, but erected over the ordinary plate floors. About 150 tons of water ballast were carried by these vessels, the filling and discharge of the tanks being effected by Downton’s pumps, worked by the crew. The trade in which they were engaged—i.e.—carrying coal from the Tyne to Spanish ports, and back to this country with ore—was one in which the introduction of water ballast proved commercially and otherwise most advantageous. Two years subsequently Messrs A. M‘Millan & Son, Dumbarton, introduced water ballast into one of the largest class of sailing vessels then being built. Unlike previous sailing ships with provision for water ballast, however, the vessel was constructed on the structural cellular bottom principle, having bracket floors and continuous girders, as so generally approved in steamships. Capacity for water ballast, to the extent of over 300 tons was thus provided, the filling and discharge being effected by a special donkey engine, supplied with steam from a large donkey boiler. The boiler[19] also furnished the motive power for cargo winches, off which, by crank gear, the manual labour pumps were also brought into requisition. Facilities for the expeditious management of ballast—the want of which, in sailing vessels, considerably hinders its adoption—were thus, in this case, efficiently provided. Several other sailing ships, built by Messrs A. M‘Millan & Son, and by other shipbuilding firms on the Clyde, have been fitted with this system, and the result of experience with these vessels in actual service, thoroughly encourages its more general adoption.

Many minor, yet aggregately important, structural features which are products of the progressive movement of recent years, or are simply revivals of old devices which were “untimely born,” still call for some notice. As a necessary consequence of the growth in dimensions and the change in relative proportions of vessels, greater regard has been paid to the systems of construction in which the longitudinal principle is involved. This, of course, is evidenced by what has been said of the cellular bottom system, but various minor structural features associated with the cellular bottom are also noteworthy in this connection. It is the practice, for instance, where large ships are concerned, to fit side stringers in the holds, throughout the entire length, made intercostal with regard to transverse plate or web-frames occurring at intervals of 16 or 20 feet, which extend from the bilge to the main deck. This arrangement—an outline of which may be found to the right of the section shown as Fig. 1—possesses many structural advantages, and finds additional favour with shipowners on account of its leaving a clearer hold for stowage by obviating the use of transverse hold beams.

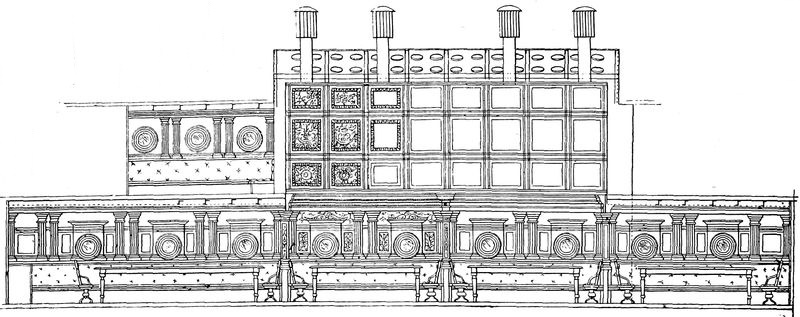

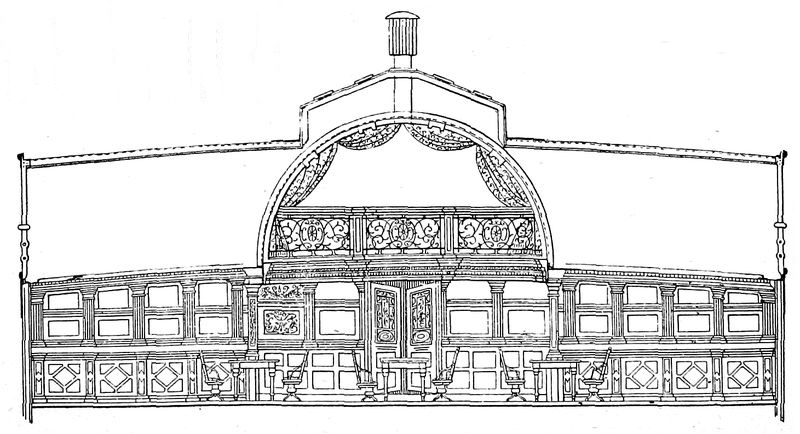

Regard for transverse strength has increasingly evinced itself in the fitting of various kinds of plate side stiffeners or partial bulkheads. This is well exemplified in a very recent case—that of the National Company’s steamship America, built by Messrs J. & G. Thomson. This vessel, having been constructed[20] independent of any special Registry Rules, embodies structural features not common amongst vessels in which such rules are undeviatingly conformed to. The system referred to, of plate frames or partial bulkheads, is one of the most conspicuous of these features. Throughout the length of the vessel, at intervals of about 18 feet, transverse plate stiffeners or frames, extending from the shell inwards about 4 feet, take the place of the ordinary angle frames, and are continuous from floors to upper deck, the stringers and other longitudinal features being scored through them. The surplus transverse strength resulting from this system is such as amply to compensate for uncommonly large breaches made in the deck beams and plating for light and air purposes in the saloons. This is a very special feature in the interior arrangement of the America, and will be referred to further on. The regard for transverse strength, again, conjointly with the increased attention to minute watertight sub-division, has led to the fitting of a greater number of complete watertight transverse bulkheads, relatively to the lengths of vessels.

In vessels of extreme proportions the method of forming shells two-ply, or of fitting all the shell plates edge to edge with outside covering-strakes over the fore-and-aft joints, has been recently revived and much improved. The system, although very expensive, has been adopted in vessels for the Anchor Line by Messrs D. & W. Henderson, Glasgow, and subsequently on even a more extensive scale by the Barrow Shipbuilding Company.

Affecting the structural character of modern ships very materially, but the result chiefly of an economy in labour, riveting by machine power has received a wonderfully extended application within recent years. Structurally, as well as commercially, the system has played a large part in the progressive movement under review. By its means the strength of united parts has been enhanced through the increase of their frictional resistance, and through the rigidity[21] of joints, due to the more thorough filling of the rivet holes. The subject of hydraulic or machine power riveting will, however, receive fuller treatment in a subsequent chapter.

Within the past two or three years cast steel stems, stern-frames, and rudders, have been taking the place of forged iron work in ship construction. The practicability of manufacturing these of such strength and homogeneity as would meet the needs of ship construction even better than the ordinary forged work, had occurred some five or six years ago to several engaged in the steel trade. Mr J. F. Hall, of Messrs William Jessop & Sons, Limited, Sheffield, had the subject under consideration about that period, and actually made several small stern posts and rudders for steam yachts and launches. The advantages of solid and uniform steel castings over iron forgings—which, with their many weldings, so often prove inefficient when subject to any sudden shock—were even then rightly enough appreciated. It was only, however, after patents had been taken out by Messrs Cooke & Mylchreest, of Liverpool, for various devices connected with the actual fitting of such features to the ship’s structure—amongst other things the hanging of rudders without pintles or gudgeons—that the manufacture of cast steel stern-frames, rudders, &c., was seriously proceeded with.

In July, 1882, the Steel Company of Scotland (Limited), who are the manufacturers in Scotland of Messrs Cooke & Mylchreest’s patent form of rudders and stern-frames, successfully cast a stern-frame—the first of large size, it is believed, made for actual use in the construction of a steamer. In April of the same year, however, Messrs William Jessop & Sons (Limited), of Sheffield, had exhibited a crucible cast steel stern-frame and rudder of their manufacture, at the Naval and Sub-Marine Exhibition, held in London. These large castings, along with others, were subjected to a series of tests in the presence of Lloyd’s inspectors and other authorities, such as the forged frames and rudders ordinarily fitted would not[22] have come through without severe damage, yet all of which the steel castings withstood most thoroughly.

Testimony to the efficiency of these new features in ship construction has already been furnished from the arena of actual experience, by the recent grounding of two steamers in which these features had been introduced. The screw-steamer Euripides, a Liverpool-owned vessel of about 1780 tons gross, completed in May, 1883, by Messrs Caird & Purdie, of Barrow, some time ago ran upon a reef of boulders, and remained thumping heavily for several hours. At the time she was laden with a full cargo of grain, which was afterwards delivered in perfect condition. The cast steel stem and stern-frame, which were manufactured by the Steel Company of Scotland, were practically without damage, notwithstanding that serious indentations were made in them. The stem, although receiving the full force of resistance, was not perceptibly altered in shape, and competent judges who inspected the damage in dock were of opinion that the stem, with its superior attachments, in all probability saved the vessel from total loss. The rudder on the Euripides is of solid cast steel, in one piece, and hung without pintles, and in a manner involving little or no riveting. In this, as in the other features, the immunity from serious damage testifies to the efficiency and durability of the steel castings. The second case of grounding referred to is that of the screw-steamer Strathnairn, of 400 tons, belonging to Messrs James Hay & Sons, of Glasgow; one of two vessels built by Messrs Burrell & Son, of Dumbarton, in which cast steel stern-frames and rudders were adopted. This vessel got aground while off Harrington, on the north-west coast of England, about the latter end of March of the present year. Her stern-frame sustained very considerable shock: such, indeed, as no ordinary forged work could possibly have undergone with like result. Subsequent docking showed that it would only be necessary to straighten the frame at the deflected portions in order to make it again structurally efficient. This was done, and the vessel is again actively engaged in service.

The weldless stern-frames, rudders, and stems, as patented by Messrs Cooke & Mylchreest, Liverpool, and manufactured for them by the Steel Company of Scotland, Messrs Jessop & Sons, Sheffield, and Messrs John Spencer & Sons, Newcastle, have various advantageous features which may be noticed somewhat fully. One of these is the casting of flanges on the stern-posts, for attaching the shell plates to; by which arrangement much of the difficult and costly work in the riveting and fitting of the shell plates at these parts is done away with, while a considerable increase of strength is obtained. The solid rudder is a great improvement on the built rudder as usually fitted; the entire absence of rivets being an important desideratum. The rivets connecting the rudder-plates to the frame-forging are frequently a source of trouble and annoyance, through their being loosened by the constant vibration of the rudder, and the shocks it often receives. The heads of the rivets not unfrequently drop off, and the rivets themselves sometimes fall completely out. All this, of course, is entirely obviated in the solid rudder. By Messrs Cooke & Mylchreest’s improved method of fitting the rudder—a device which is only applicable in a casting—pintles are wholly dispensed with, and in their place a much stronger joint is substituted, with a considerably increased wearing surface. The rudder is also jointed at the top of the blade, by means of strong flanges bolted together; an obvious advantage of this arrangement being that it can be readily unshipped, even when afloat.

In addition to the stern-frames, stems, and rudders, there are, also being supplied, keels, garboard strakes, and centre keelsons in long lengths. It is claimed for these that as the keel, garboard strake, keelson, and brackets for connecting the floors, are all made in one piece, they are much stronger than as ordinarily constructed, and that a considerable saving in both labour and rivets is effected. As there are no angle irons to contend with, the limber-holes may be made close to the bottom plating, and a much thinner layer of cement will, consequently, be needed on the bottom; the saving in this respect, according to the patentees’ calculation, being 50 tons in a 2,000-ton vessel.

As the prices of these frames and rudders do not exceed those charged for frames of wrought-iron, and moreover, owing to the pieces which are cast on to them forming attachments for keels, decks, &c.—thus cheapening the work of construction in the shipyard—there appears to be no question of their great superiority. The presence of blow-holes, not unfrequently a source of misgiving in castings, is found from experience to be a constantly diminishing fault in these articles. The demand for them has steadily grown since their adoption in a few actual cases. It would seem, indeed, that the demand is only limited by the powers of production possessed at present by the four or five steel-making firms who have undertaken this class of work, and have satisfied the requirements of the registration and the insurance societies.

In addition to the frames and rudders for ordinary screw vessels, the Steel Company of Scotland have also supplied several sterns for war vessels, with rams and torpedo openings, which have proved very satisfactory. Other new adaptations are the casting of large brackets for shafts of twin screw vessels, of large crank shafts themselves, and of heavy anchors; the results of tests presently being made fully warranting the anticipation that the material will very largely be employed in the future for these important items in the outfit of merchant vessels.

The more important features of growth or change in ship construction which have made the past few years a noteworthy period in the history of mercantile shipbuilding have now been reviewed. Speed, and propulsive power of steamships, although absorbing very much of the progress for which the period has been so remarkable, have not been dealt with, but are reserved for the chapter following. The subjects named will also necessarily receive some attention in the chapter devoted to progress in the science of shipbuilding. In anticipation, however, apologies should be offered for the paucity of detailed references to the propulsive agents on board ship.[25] Marine engineering, in all its recent developments, would require for its proper treatment considerably more space than can be devoted to it in the present work.

To meet the exigencies of the progressive movement, both practical skill, scientific knowledge, and commercial enterprise have been needed on the part of our shipbuilders. These have not been by any means wanting, as abundantly evidenced by the foregoing record of what has been achieved. With a continuance of that readiness displayed by shipbuilders and naval architects to modify, and even revolutionize if need be, types and methods which the times have outgrown, the lead in merchant shipbuilding will long be ours. With a maintenance also of the enterprise shown by our shipowners, Britain will still continue, as regards the number, size, and power of her merchant ships, supreme among the nations.

List of Papers and Lectures bearing on recent improvements in ship design and construction, to which readers desiring fuller acquaintance with the technique and details of the subjects are referred:—

On a New Mode of Constructing Iron and Composite Ships, by Mr J. E. Scott: Trans. Inst. Engineers and Shipbuilders, vol. xv., 1871-2.

On the Strength of Iron Ships, by Mr William John: Trans. Inst. N.A., vol. xv., 1874.

On Transverse and Other Strains of Ships, by Mr William John: Trans. Inst., N.A., vol. xviii., 1877.

On a System of Shipbuilding Combining Transverse and Longitudinal Framing, by Mr James Hamilton, Jun.: Trans. Inst. Engineers and Shipbuilders, vol. xviii., 1877-88.

On the Longitudinal Bulkhead System of Iron Ship Construction, by Mr Edwin W. De Russet, Trans. Inst. N.A., vol. xvii., 1876.

On Iron and Steel for Shipbuilding, by Mr Nathaniel Barnaby: Trans. Inst. N.A., vol. xvi., 1875.

On Steel for Shipbuilding, by Mr Benjamin Martell: Trans. Inst., N.A., vol. xix., 1878.

On the Use of Mild Steel for Shipbuilding in the French Dockyards, by M. Marc Berrier-Fontaine: Trans. Inst., N.A., vol. xxii., 1881.

On Steel in the Shipbuilding Yard, by Mr William Denny: Trans. Inst. N.A., vol. xxi., 1880.

On the Economical Advantages of Steel Shipbuilding, by Mr Wm. Denny: Journal (No. 1) Iron and Steel Institute, 1881.

On Iron and Steel as Constructive Materials for Ships, by Mr John Price. Proceedings Inst. Mech. Engineers, 1881.

On Steel, by Mr James Riley; Lectures on Naval Architecture and Marine Engineering: Glasgow, William Collins & Sons, 1881.

On Water Ballast, by Mr Benjamin Martell: Trans. Inst. N.A., vol. xviii., 1877.

On the Cellular Construction of Merchant Ships, by Mr William John: Trans. Inst. N.A., vol. xxi., 1880.

On the Increased Use of Steel in Shipbuilding and Marine Engineering, by Mr John R. Ravenhill: Trans. Inst. N.A., vol. xxii., 1881.

On the Structural Arrangements and Proportions of H.M.S. “Iris,” by Mr W. H. White: Trans. Inst. N.A., vol. xx., 1879.

On the Quality of Materials used in Shipbuilding, by Mr H. H. West: Trans. Inst. N.A., vol. xxiii., 1882.

On the Use of Steel Castings in lieu of Iron and Steel Forgings for Ship and Marine Engine Construction, by Mr William Parker: Journal, Iron and Steel Institute, 1883.

Some Considerations Respecting the Rivetting of Iron Ships, by Mr Henry H. West: Trans. Inst. N.A., vol. xxv., 1884.

Recent Improvements in Iron and Steel Shipbuilding, by Mr William John: Iron and Steel Institute, 1884.

In these days of feverish activity in every avenue of business, when even leisure has come to be observed at a much more accelerated tempo than formerly, speed in locomotion would seem to be the first desideratum, not only on shore but afloat as well. In no ocean service is the truth of this so apparent as in the transatlantic mail and passenger service, the oldest and most constantly progressive, and where at the present time, certainly more than at any former period, the contest for supremacy amongst rival steamship lines has assumed the form of increased speed and enhanced passenger accommodation.

The Atlantic service, for these reasons, as well as because it exemplifies more of the fruits which have rewarded the joint labours of the engineer and shipbuilder in improving marine propulsion, may be selected for detailed review. In other ocean services, of course, the achievements of engineering and shipbuilding skill have also been made apparent, and in ways, perhaps, which the Atlantic service does not exhibit. Reference to these will afterwards be made, but attention will meantime be confined to the service stated, and to such considerations of the general progress made in ocean navigation as are necessarily involved in the particular subject.

It is needless, in view of the frequency with which the story of ocean steam navigation is told, and especially, considering the scope of the present review, to enter at any length into the details of early service. The first practically successful transatlantic steamers were the Sirius and the Great Western, the first a paddle-steamer 170 feet long, 270 horse-power[28] originally constructed to ply between London and Cork, and the latter, a paddle-steamer, 212 feet long and about 440 horse-power, designed and built expressly for the transatlantic service. The Sirius left Cork on the 4th April, 1838, and reached New York on the 22nd; the Great Western left Bristol on the 7th April, three days after the Sirius, reaching New York on the 23rd—the time taken being thus 18 days and 15 days respectively. The return voyages of these pioneer long-passage steamers were made in 16 days and 14 days respectively, their performances at once establishing the superiority of steamers, commercially and otherwise, over the sailing ships which had previously for so long been the recognised medium of transit in the Atlantic passenger trade.

In 1840 a regular mail service by steamers was first introduced on the Atlantic. The first of these mail steamers was the Cunard paddle-steamer Britannia, 207 feet long, which sailed from Liverpool on July 4, 1840, and arrived at Halifax in 12 days 10 hours, the return journey being performed in 10 days. The Acadia, Columbia, and Caledonia all of about the same dimensions as the Britannia, at once followed. The success of the Cunard Line was so marked that opposition was soon provoked, and in 1850 the Collins Line of American steamers started to compete with the Cunard liners. The same year also saw the commencement of the well-known Inman Company, of Liverpool, their first vessel being the City of Glasgow, an iron screw-steamer of 1680 tons and 350 horse-power. The Allan and Anchor Lines were established in 1856, the Guion Line in 1863, and the White Star Line in 1870.

With the substitution of the screw propeller for the paddle wheel, first carried out to any great purpose in the small steamer Archimedes in 1839, but introduced with even greater effect in the Atlantic steamer Great Britain in 1843, was laid the basis of that progressive and magnificent success in propulsion which has since attended ocean navigation. It was with screw-steamers Mr Inman boldly assailed the Cunard Company in 1850, but notwithstanding this, it was only in 1862 that the Government consented to sanction the use of[29] the screw in the mail steamers of the Cunard Company. The Scotia, measuring 366 feet in length, by 47½ feet in breadth, and 30½ feet depth, launched in 1861, was the last paddle-steamer built for this company.

The other great improvements contributing to the success spoken of, were the introduction of engines designed on the compound principle, and a little later, the employment of the surface condenser, and the use of circular multitubular boilers. In spite of the success with which the compound system was attended in vessels built for the Pacific Steam Navigation Company as early as 1856, and for some other private owners soon after, the great steamship companies, and shipowners generally, were very slow to adopt it. It was not until about the year 1869 that the compound engine came into general use, and it was only in 1872 that the Cunard Company seriously took it into favour.

The early steamers of the Cunard Line possessed an average speed of 8½ knots, and took about 15 days for the voyage. Through the Collins rivalry the speed was increased to an average of 12½ knots, and the time for crossing the Atlantic was reduced to 12 days 9 hours outwards, and 11 days 11 hours homewards. In 1856, the powerful paddle-steamer Persia (the first iron vessel built for the Cunard Company) was placed on the service, and attained an average speed of about 13 knots, consuming 150 tons of coal per day. She made the distance between Queenstown and New York, on an average, in 10½ days. In 1862 the Scotia, belonging to the same company, made the passage in 9 days.

Coming down to more recent times, the White Star Line, with its steamships Britannic and Germanic, built in 1874 and 1875 respectively, held for a considerable period first place in the matter of fast steamships. The vessels named were, however, in time beaten by the newer ships Gallia, of the Cunard Line, and Arizona, of the Guion Line. As illustrating the speed at which the vessels named accomplished the transatlantic voyage—between Queenstown and New York—the following brief list, compiled from published records, of fast[30] runs out and home during the period 1875-1881, may here be given:—

| Vessels. | Out. | Home. | ||||||

|---|---|---|---|---|---|---|---|---|

| Date. | Time. | Date. | Time. | |||||

| D. | H. | M. | D. | H. | M. | |||

| Britannic, | Aug., 1877, | 7 | 10 | 50 | —— | —— | ||

| Britannic, | May, 1879, | 7 | 13 | 7 | May, 1880, | 7 | 19 | 22 |

| Germanic, | Oct., 1880, | 7 | 13 | 0 | Nov., 1881, | 7 | 17 | 34 |

| City of Berlin, | Oct., 1877, | 7 | 14 | 12 | Oct., 1875, | 7 | 15 | 48 |

| City of Berlin, | Oct., 1880, | 7 | 20 | 32 | Sep., 1879, | 7 | 19 | 23 |

| City of Richmond, | Oct., 1880, | 8 | 0 | 0 | July, 1879, | 8 | 3 | 52 |

| Gallia, | May, 1879, | 7 | 22 | 50 | May, 1881, | 7 | 18 | 50 |

| Arizona, | Sep., 1881, | 7 | 8 | 32 | Sep., 1881, | 7 | 7 | 48 |

When the success of vessels of the size of the Arizona and the Gallia was made apparent, it was decided by the Cunard Company to build a larger and faster ship than previous ones. Accordingly, in the autumn of 1880, specifications were issued to some of the leading shipbuilding firms, asking them to tender for the construction of a vessel of 500 feet in length, 50 feet beam, and 40 feet depth. At the suggestion of Messrs J. & G. Thomson, who were successful in securing the contract for this remarkable vessel, the dimensions were increased to 530 feet by 52 feet by 44 feet 9 inches. With these dimensions, and with mild steel as the constructive material, the new vessel—the Servia—was thereafter proceeded with in Messrs Thomson’s establishment.

The Guion line, not to be left behind, placed the order for a vessel of the dimensions first proposed for the Servia, with Messrs John Elder & Co., but, in order to be faster than the Servia, the weight-carrying was considerably reduced, and the boiler power much increased. The wisdom of this step has been justified by the now generally received opinion that these fast steamers should not carry such heavy cargoes as the slower ones. This new vessel for the Guion line was the Alaska, now justly noted for her fast runs across the Atlantic.

The Inman Company also decided not to lag behind, and as soon as the conditions of the design of the Servia had been fixed, they placed the order for a ship—the City of Rome—with the Barrow Shipbuilding Company, intended to be larger, finer,[31] and faster. Expectations as to speed and carrying powers were not in her case fulfilled, and the result of the dissatisfaction which this occasioned, was, that the City of Rome changed ownership, Messrs Henderson Brothers, of Anchor Line fame, coming into possession. In the hands of its new owners, the City of Rome was re-arranged internally, and her boiler power was considerably augmented, while her engines also were thoroughly revised. When first built, the vessel was fitted with engines of 8500 horse-power. As revised, they indicate 12,000 the acquisition being largely due to the fitting of four additional boilers. The results which have accrued from the extensive alterations made are such as to have firmly established the vessel in a foremost place in the Atlantic service.

The performances of the vessels named have been the subject of considerable interest to all concerned in shipping affairs, and to the public generally. The following table of fast passages accomplished during the past two years by these vessels has been compiled from published records, and from information supplied by the shipowning companies:—

| Names of Vessels. | Out. | Home. | ||||||

|---|---|---|---|---|---|---|---|---|

| Date. | Time. | Date. | Time. | |||||

| D. | H. | M. | D. | H. | M. | |||

| Alaska, | April, 1882, | 7 | 4 | 32 | June, 1882, | 6 | 22 | 0 |

| Do., | May, 1882, | 7 | 7 | 0 | Sep., 1882, | 6 | 21 | 48 |

| Do., | May, 1882, | 7 | 4 | 10 | Jan., 1883, | 6 | 23 | 42 |

| Servia, | Jan., 1882, | 7 | 8 | 13 | —— | —— | ||

| Do., | Aug., 1883, | 7 | 6 | 0 | —— | —— | ||

| City of Rome, | May, 1883, | 7 | 12 | 16 | June, 1883, | 7 | 7 | 4 |

| Do., | June, 1883, | 7 | 4 | 56 | July, 1883, | 7 | 2 | 19 |

| Do., | Aug., 1883, | 6 | 22 | 6 | Aug., 1883, | 6 | 21 | 4 |

| Do., | Sep., 1883, | 7 | 3 | 0 | Sep., 1883, | 6 | 23 | 24 |

An addition to the list of competitors was made in the Aurania, built by Messrs Thomson in 1882, and tried in June, 1883, when she attained a mean speed of 17¾ knots, and showed herself not unequal to a maximum speed of 18½ knots under circumstances ordinarily favourable. An untoward and serious accident to her machinery laid the Aurania aside just[32] as her capabilities in actual service were being shown. It is during the “passenger season” that the qualities of these transatlantic steamers are best brought out, and it remains with the season which has just begun, to demonstrate to the full the Aurania’s powers.

A similar remark applies to the Oregon, a still more recent competitor from the same stocks as the Alaska, whose dimensions correspond with those of the Alaska, except in respect to breadth, the first-named vessel having 3-ft. 6-in. more beam than the latter, the figures being—length over all, 520-ft.; breadth, 54-ft.; depth, 40-ft. 9-in. Extra power of engines to the extent of nearly 3000 horses indicated has been fitted in the Oregon. On the occasion of her speed trial on the Clyde she ran the distance between Ailsa Craig and Cumbrae Head—-29½ nautical miles—in 1 hour 20 minutes, or about equal to 20 knots per hour. This was attained with the engines indicating 12,382 horse-power and making 62 revolutions per minute, the steam pressure being 110-lbs. per square inch. This result was doubtless attained under conditions more favourable to speed than the vessel is, as a rule, likely to meet with in actual service; and, as has been indicated, it still remains with the future to determine how far the aims of the owners and builders of the Oregon are realised.[1]

In the America, launched from the yard of Messrs J. & G. Thomson, near the close of 1883, and presently being fitted for sea, the National Steamship Company (Limited), of Liverpool, have embodied the results of their careful study of the development and changes in the mode of conducting the American trade. From such experiments—for they can hardly be considered[33] anything else—as the rapid passages of the Alaska, the City of Rome, and other “greyhounds of the Atlantic,” the company see it is no longer possible or profitable to have “composite” vessels—i.e., those intended to carry a large cargo as well as passengers,—but that practically one class of vessels must be built for the passenger traffic and another for the conveyance of cargo. The vessel represents an attempt to solve the problem of producing a ship which shall have large passenger accommodation and a high speed, with a comparatively small first cost and a reasonable consumption of coal. She is built of steel, and of the following dimensions:—Length, 440 feet; breadth, 51¼ feet; depth of hold, 36 feet; gross tonnage, about 6,000 tons. Her engines are of the inverted three-cylinder type, the high pressure cylinder being 63-ins. diameter, the two low pressure cylinders being 91-ins. each, while the piston stroke is 66-ins. Six double ended boilers and one single ended, having in all 39 furnaces, are fitted. The power expected to be developed is about 9,000 indicated. The speed guaranteed by the builders of the America is 18 knots an hour, and confidence is entertained by all concerned as to this result being attained.[2]

It is abundantly evident, notwithstanding what has already been achieved, that the brisk competition among transatlantic companies for the “fastest steamer afloat” has not yet exhausted itself. The determination some time ago publicly expressed by Mr John Burns, the able chairman of the Cunard Company, to maintain a leading position, has since taken decidedly active shape in the contract entered into and now being carried out by Messrs John Elder & Co.: that is, the construction of the two huge and powerful steamers of unprecedented speed, already referred to near the beginning of this work. They are each of 8000 tons burthen, 500 feet in length, 57 feet broad, by 40 feet depth of hold. Engines of 13,000 horse-power[34] will be provided, which, it is computed, will drive the vessels at a speed of 19 knots an hour. With the establishment of these remarkable steamships in this most important service, the prospect is near of a transatlantic passage lasting only six days, if not indeed considerably under that period.